-

Français

Français

-

English

English

No products

Prices are tax included

How to choose a drum filter suited to your needs?

Among the dozens of brands of drum filters, it is indeed very difficult to find your way: which is why you will undoubtedly read these few lines.

The current market being saturated with manufacturers and just as many resellers, it must be recognized that very often misinformation prevails over good communication of precise and reliable data. This situation generates a lot of questions and unfortunately bad purchases ensue because we could not find the right pipes.

But when you have spent several thousand Euros, for most, it is too late!

Here are some ideas, and some pitfalls to avoid.

First of all the price: believe it or not but we have been selling pond equipment for over 17 years and one thing is certain, quality has a price and you will never find a reliable and efficient machine cheap!

The market being very aggressive, it tends for prices to fall, but for this, manufacturers must inevitably find solutions or tricks: as always - and to the displeasure of some - a filter which resembles another filter on photo is always very different when you have the opportunity to compare the two machines in front of you.

We will come back to prices and how to approach them a little later.

Filtration mode

Let's move on to the basics: the vast majority of drum filters are designed and delivered to operate in gravity mode.

Normal, since they are intended for Koi ponds. But paradoxically, the majority of ponds are still - unfortunately - built in pumping mode and in this case, certain details are very important.

The filters are offered in a pumping version or in a gravity version: others are convertible and are therefore - from the same machine - usable in one or the other system with a slight adaptation provided by the manufacturer. A previous page has already discussed the advantages/disadvantages of each filtration mode: it is obvious that a modern installation must operate in gravity mode. If you do not know the difference between these two filtration modes, I invite you to visit this page before continuing reading about the drum filter. https://www.bassin-baignade.eu/en/content/23-les-modes-de-filtration

Before detailing the technique, you must also know how a drum filter works.

General operation

The filter consists of a tank in which a rotating drum is housed: this drum is covered with a filter membrane on its periphery.

Dirty water from the pond is directed inside the drum and, to leave this filter, the water must pass through the filter membrane. The water from the pool, which is free of particles, leaves the filter and is directed towards the biological part.

As the dirty water passes through the drum, the particles are deposited, blocking the small holes in the membrane which gradually becomes clogged. The passage of water is therefore slowed down, which causes a difference in level between the downstream and upstream sides of the sieve.

At this time, the detection system starts a drum cleaning cycle. From this moment, the drum rotates very slowly and the nozzles placed on the upper part (external side of the drum) project jets of water onto the filter membrane: under the pressure of the water, the smallest dirt is expelled from the filter membrane.

This dirt is collected in a gutter and directed outside the filter. The upstream/downstream water level is restored until the next cycle.

This cleaning is minimalist: the drum does not rotate continuously, it only intervenes when necessary: the consumption of water and electricity is therefore negligible.

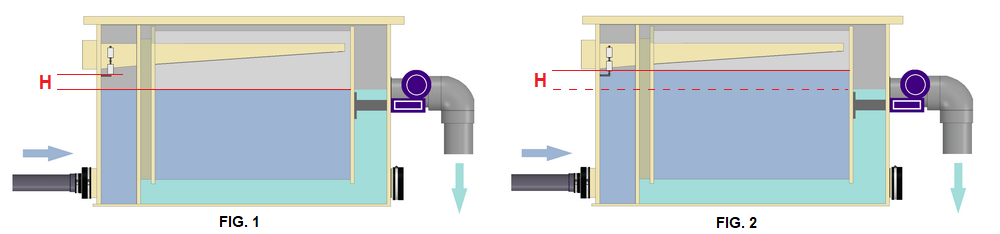

Operation in pumping mode

A pump pumps the water from the pool into the filter, the dirt remains trapped in the drum, and the filtered water flows from the drum filter to the biological filter (fig. 1)

As the water passes through, the drum gradually becomes clogged, the water level rises in the drum until the sensor located in the pre-chamber activates a rinse of the filter (fig.2) . The second float of the sensor shown (the top float) allows the entire system to be shut down in the event of a failure.

Gravity mode operation

Same drum filter, but configured in gravity mode: the water in the pool is at the same level as in the filter (principle of communicating vessels).

A pump draws the water into the filter, the dirt contained in the pond water remains trapped in the drum, and the filtered water flows towards the biological filter (fig. 1)

As the water passes through, the drum gradually becomes clogged, the water level drops in the chamber around the drum until the sensor activates a filter rinse (fig.2). We see that in gravity mode, the sensor is no longer located in the pre-chamber, but in the second chamber which contains the water already filtered by the drum membrane.

The second float of the sensor shown (the float below) allows the entire system to be shut down in the event of a failure.

Drum size

The size of the filter is the major element which can tell you about the capacity of the filter to treat the waste from your pond.

The larger the drum, the less rinsing it will have to do, for a precise and known flow rate.

Since a Koi pond is generally filtered in two hours (*), it is not enough to choose a filter whose advertised flow rate corresponds to your needs... too easy!

The characteristics announced by manufacturers are often taken from tests carried out indoors and the values are often rounded upwards in order to make the equipment sexier!

At best, the filter will accept the flow rate announced by a seller, but the latter will fail to tell you that the filter will rinse every 5 minutes...

A filter should normally flush 3 to 4 times per hour maximum during the summer months. Much less in autumn or spring.

In winter, the filter will only rinse once or twice a day.

These figures are an average and vary depending on many parameters: poisoning density, presence or absence of plants in the pool, proximity to trees or dense vegetation around the pool, etc.

Second trap, the size of the filter to take into account is not that of the body, but that of the drum.

A 1.20 m filter may ultimately turn out to be smaller than a 0.80 m filter from another brand: as the sieve is the element to be taken into consideration, it is necessary to compare the useful sieve surface, therefore the one which is actually immersed in water and which sifts the water from the pool. Large diameter drums often offer more useful surface areas than long, small diameter drums. These figures are rarely communicated and you often have to calculate them yourself.

Regarding our store: the house policy is to communicate the figures announced by the manufacturers and there will never be any question of modifying them for any reason whatsoever.

During an interview, we therefore sometimes weight these sometimes exaggerated figures (this applies to other equipment) but the indications provided by the manufacturers are respected on our sales site.

A pool by its construction is unique, and in our opinion, no brand can claim today to be able to meet all the particularities, nor all the budgets.

This is why it is essential to spend one or two hours gathering all the data from the basin and its network, to define the most suitable filter model(s).

In short, the pelvis in pumping mode of a sedentary pensioner requires different attention from the pelvis of the business manager who works 60 or 70 hours a week, or even the “collector” who has valuable subjects in his pelvis .

There are so many different wishes and temperaments that there too, there would be room for discussion...

Conclusion: the size of the drum is one of the major elements for choosing a filter, but it still needs to be determined precisely to compare it to other models: afterward, it only remains a filter... Are you sure you can adapt it to YOUR pool?

(*)

Some are convinced that the water quality is better if the pool is filtered within 1 hour.

In absolute terms, this is true, but at the expense of electrical consumption (the pool pumps, and not because of the filter) but visually this is not visible. Exception, small ponds in gravity mode must be filtered in 1 hour, but for other reasons...

Medium-sized pools up to 40 - 50 m3 can turn without problem in 2 hours: for larger ones between 2 and 4 hours depending on the type of pool.

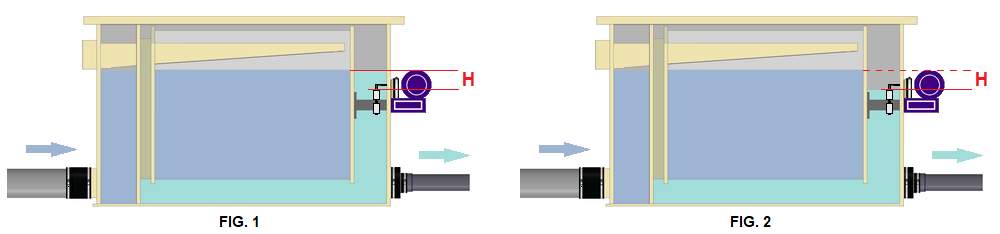

Below are three examples of filters of very different sizes.

Mechanical filter alone or with bio filter (Combi)

Manufacturers often offer mechanical filters (drum) in a box also containing a biological compartment with pre-installation of ventilation and the UVC system. This type of Combi can be interesting for non-do-it-yourselfers and we can note the advantages and disadvantages.

The advantages are as follows: reduced footprint, no hassle for drum connection >< biological filter, generally a location for one or more immersion UV rays is provided, the finishing of a Combi set is often more successful than a mixed installation.... So speed of execution without risk of error, the professionals understand this.

Disadvantage, there is only one main: according to some, the biological volume is often too small. But by respecting a reasonable stocking density (1 adult Koi for 2 to 3 m3 of water), these Combis are nevertheless suitable, even if we are not against the installation of large organic filters.

Unfortunately, too often, the stocking density is too high (we read on many forums or social networks a density of 1Koi per m3, which is too much) in this case, it is necessary to resize the size of the biological filter.

Either we add a second biological filter to a Combi, or we opt for an insulated drum filter after which we install a large biological filter composed of several modules.

By comparing the many filter models, we ultimately find ourselves faced with many possible combinations: but isn't it better to be spoiled for choice rather than the opposite?

Below a drum filter (mechanical filtration) and a Combi (drum filter + biological filtration in the same module)

Matter and materials

Different materials are used for the construction of a filter: synthetic materials such as polypropylene (PP), high density polyethylene (HDPE) or even stainless steel.

Some internal components may be made of PVC, ABS or POM....

You will mainly find 100% synthetic PP filters, filters made up of a PP frame with internal equipment (drum, chute, etc.) in stainless steel, and 100% stainless steel filters.

With the exception of small, very compact filters (10 m3/h) made in an extruded synthetic box (one piece), the filters are made up of welded elements: whether for synthetic or stainless steel.

Some models are made from previously folded steel sheets which are then assembled with bolts: this technique offers in certain cases certain advantages...

The budget may orient towards synthetic or stainless steel... but one thing is certain, the market now offers PP filters that are just as strong and effective as stainless steel models.

In terms of durability, a synthetic filter will remain intact and in perfect condition in its technical room, even after several decades!

And contrary to popular belief, this is not necessarily the case for stainless steel which remains sensitive to corrosion: this corrosion can be of cavernous origin, galvanic, poor passivation, etc. Reason why certain categories of professionals prefer synthetic to stainless steel: insensitive to salt, to many chemicals, electrical insulator, PP does not experience the problems of a metal filter which is conductive, etc.

Polypropylene is rot-proof, chemically inert and its lifespan is longer than stainless steel, to the great dismay of some (ill-informed) ecologists... because it is 100% recyclable!

On this level, because many of you are sensitive to this ecological argument, it takes much less energy to manufacture a synthetic filter than an equivalent model in stainless steel, so paradoxically, the synthetic filter is more ecological! Some people suggest resistance problems depending on the temperature: well, just consult the technical sheet for this material to see that it holds up very well from -20° to + 100°C!

It is true that at a temperature close to 30°C the material becomes a little more malleable: large panels can let themselves come into contact with lukewarm water, but this is only seen on large panels (> 2 m2) without reinforcements, which is never the case with drum filters which are too small to deform and which, in addition, have reinforcements...

Some resellers highlight the thickness of the panels.... Yes, but under the effect of heat, a 12 mm panel deforms just as well as a 10 mm panel: it is therefore not the The thickness of the panel which counts the most, but the presence of transverse reinforcements judiciously welded to hold the panels!

As for efficiency, well it does not depend on the material but on the components, the sophistication, the research and the experience of the manufacturers.

Now let's talk about stainless steel, or stainless steels....

Contrary to its name, stainless steel oxidizes, but depending on the type and quality of the alloy, a more or less protective layer will form on the material.

This “passive” layer can nevertheless allow rust to appear if the machining is not perfectly mastered: lack of passivation, contamination with unsuitable tools... are the doors open to corrosion.

The type of alloy used is an indicator of the quality of the filter: stainless steel 304, 316, 316 L or Ti.... These alloys offer different characteristics, 316 Ti being the best on the current market.

So, stainless steel “stronger than synthetic”? Yes, provided you choose a reliable brand with experience in the field. It comes down to few manufacturers excluding Asian constructions which offer a good price rather than good material.

Conclusion: it is better to acquire a good synthetic filter, rather than a bad stainless steel one. To convince yourself, compare the prices of a stainless steel sheet and a PP plate, you will be surprised to find that stainless steel is cheaper!

And if you opt for a stainless steel machine, only use well-known and recognized brands that offer solid guarantees and real, fast and efficient after-sales service! Only experts in the field can offer solid and reliable machines!

The sieve and its membrane

As standard, we will most often find 120 micron stainless steel membranes.

Some manufacturers offer 70 micron (exactly 63 microns) or 50 micron membranes as standard.

In the field of ponds, 50 microns is a maximum.... We can go beyond in aquariums or indoor ponds but these are special cases to study. In our store we offer three sizes, 120, 63 or 50 microns.

Filters equipped with 120 micron fabrics are a little less good indeed, but nevertheless suitable for most garden ponds.

Wanting to acquire a standard filter and modify it with a 50 micron membrane is an error: you must keep the relationship between size of the sieve and size of the drum... For the rest, you should know that a filter membrane is a part of wear: but let's put it into perspective because if well maintained, this membrane will hold its shape for at least ten years without problem.

Depending on the degree of hardness of the water used in the pool, the filter membrane may become scaled without it being visible. But little by little, the limestone settles on the sieve and gradually obstructs the membrane.

The filter therefore launches a rinsing cycle and the frequency of these cycles increases to the point that the filter operates continuously. When the filter is equipped with a safety device, it turns off....

Minimal maintenance is required to avoid this problem: it requires 10 - 15 minutes, twice a year.

The details of this procedure are indicated here https://www.bassin-baignade.eu/en/content/70-entretien-d-une-membrane-de-filtre-a-tambour

Conclusion: filtration fineness and filtration flow rate are closely related. Remember that a pool filtered in 2 hours, equipped with a 70 micron membrane filter should provide complete satisfaction. It will be better with a 50 micron membrane, we agree, but it is more expensive.

Level sensors

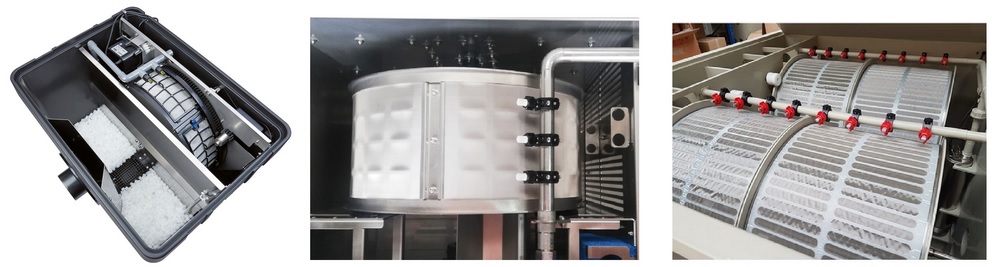

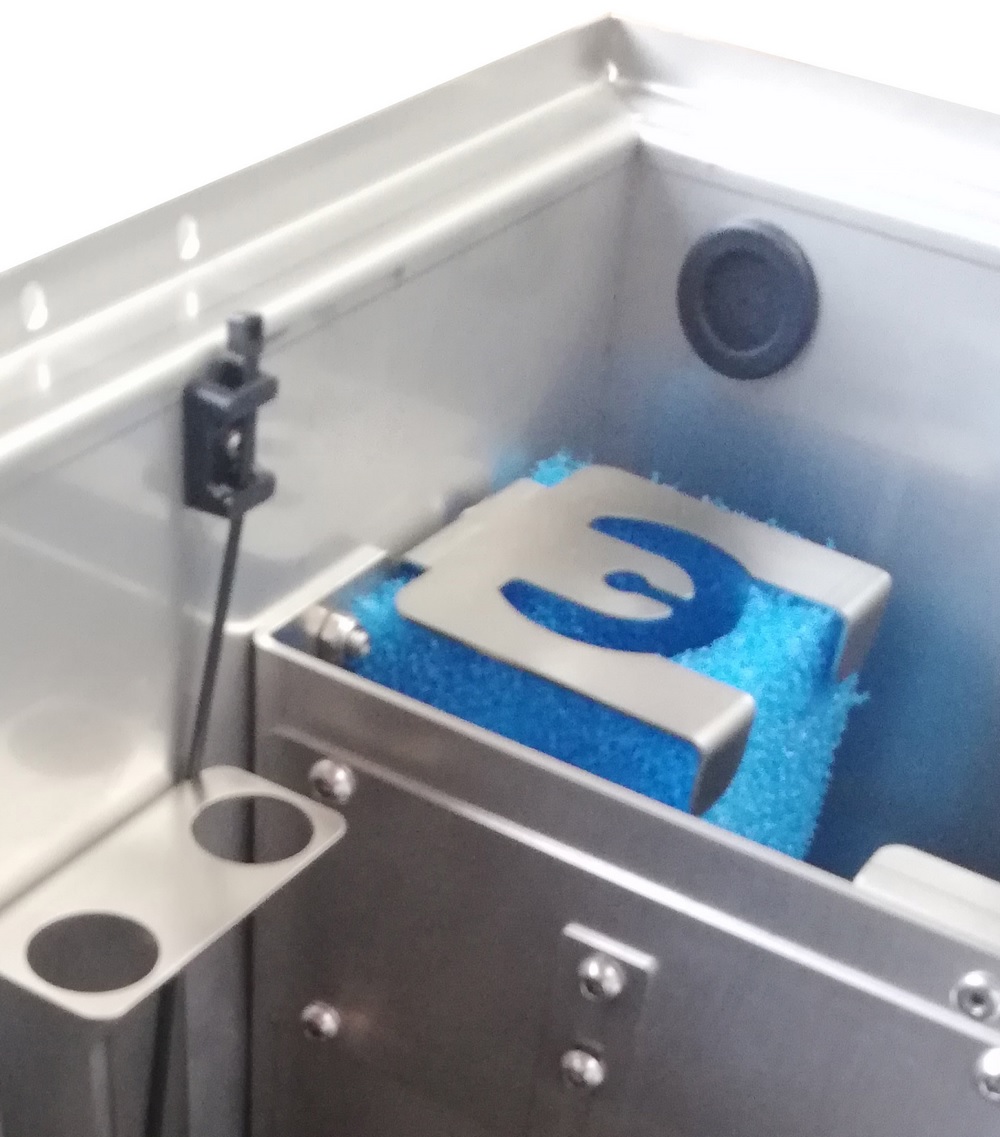

The role of the sensors is to trigger the rinsing of the filter at the appropriate time, and to ensure the safety of the system. Either avoid overflowing in pumping mode, or on the contrary emptying the filter in gravity mode. There are mainly 3 types of sensors:

- either with floats: these are detectors with a mobile float with two positions "high state" and "low state".

- either with a membrane: the analog or sometimes digital sensor transforms a physical movement into an electrical signal.

- either with two or three electrodes: we are talking here about a conductive level sensor. Current (signal) passes from one electrode to another when water, which is conductive, brings these electrodes into contact.

In pumping mode, the sensor is placed on the raw water side while in gravity mode, the sensor is placed on the clean water side, therefore the side where the water comes out filtered by the membrane. Sometimes a more savvy manufacturer has sensors on both sides of the drum.

In pumping mode, contaminated water which contains large particles and algae is in contact with the sensor.

If it is a float sensor, it risks being blocked by this algae. Hence the need for protection around this sensor to avoid overflowing of the filter (a drop in the level of the pool, etc.) or other problems. The problem does not arise in gravity mode since the water in contact is clean. Membrane or electrode sensors are insensitive to this dirt.

Below is an example of a sensor holder fitted with protective foam.

Filter training

The drum resting on rollers, it is driven by a motor: choose a large, powerful, direct-drive gear motor on your machine, rather than a micro-motor.

A source of repeated problems, these small motors are tolerated on small compact filters (< 10 m3/h) but on real good filters, a gear motor will wear out much less quickly. We note that in the presence of algae, the drum being heavily used, these small motors heat up abnormally and carbonize....

As for the toothed crown and pinion drive, it is suitable enough for very small models. On large machines, they are always the number one source of problems due to the wear which causes cascading damage.

The rinse pump

During the cleaning phase, a pressure pump draws water into the filter, to deliver it under pressure into the rinsing ramp which contains the sprayers.

This pump is most often offered in a submerged version: that is, it is installed in the “filtered water” compartment of the filter.

This provides several advantages: placed in the filter, it will not risk freezing, unlike an external pump and does not emit any perceptible noise.

External pumps are just as valid, provided they allow sufficient pressure (> 4 b), but are more fragile in winter, and emit a lot of noise.

Currently, only low-end or "first price" filters include an external pump.

Sound level

The choice of filter can be decisive if it is placed under gratings near the house.

In summer, the filter should normally rinse every 20 minutes, lasting 10 to 15 seconds.

If the noise generated by the filter is significant, this can cause, if not discomfort, sometimes neighborhood problems.

To give an idea, a good filter, with an internal submerged pressure pump, and noise protection generates noise at a level of 50 –55 dB, the equivalent of a very good dishwasher or coffee maker.

But an external booster alone generates nearly 70 dB, i.e. the sound emitted by a vacuum cleaner or an electric shaver: if in addition, the filter is not soundproofed, we then reach 75 to 80 dB, i.e. the noise emitted by a lawnmower or a ringing telephone. If the filter of your choice includes an external booster, make sure that it is of a known brand and has the lowest possible noise level.

The controller

The regulation mainly controls the operation of the filter: via sensors, it will trigger the motor, the rinsing pump, etc. at the desired time.

At a minimum, you will also have a lack of water safety device as well as an open cover detection (which shuts off the entire system if you lift the filter cover).

Some manufacturers offer much more, as standard or as an option: ease of adjusting the duration of drum rotation, ease of language in the case of a digital controller, external control possible by Smartphone, collection of data in order to check the frequency of rinsing etc. etc.

The basic controller is obviously still standard: afterward, it's up to you to see what options can be added. Once again, opt for a brand offering decent after-sales service (i.e. accessible telephone, Hot-Line, etc.)

Filter connected or not?

For several years now, some manufacturers have been offering connected filters.

You have to ask yourself the question of how YOU will use it... It's not enough to say that it's useless because you're at home all the time... Connected filters offer a multitude of functionalities that 'a simple controller cannot perform. So it's not just remote management that is useful, but many additional settings and possibilities.

This type of controller is therefore connected to the network and communicates with your filter (the filter and its auxiliaries are connected by a wired network) and you communicate via WiFi with the controller. From your home to your home, or from anywhere in the world.

For the most useful adjustments we have the choice of the duration of rotation of the drum, the frequency of rinsing of the evacuation chute and the pre-chamber (the sieve is always rinsed depending on the position of the sensors). It is also possible to remotely operate the auxiliaries (UVC, water or air pumps, etc.) and receive a notification in the event of a failure.

The controller also indicates the number of rinses carried out during a specific period. A report which records all the actions carried out by the filter is also viewable.

If this interests you, opt for a reputable brand: connectivity means constant evolution of the interface, advanced after-sales service.... There are not many good ones in this area. Also pay attention to the conditions of use: we are resellers of connected systems without subscription!

Service

This is also an important parameter!

Good service consists first of all in giving you good advice before purchasing anything: if possible in store, not in front of a PC screen.

On PC, all machines are the same: you have to see the hardware “in real life” and if possible in front of many models from different brands: the only valid way to compare and get an idea of the hardware.

The service continues with the development of the basin: a good filter is not enough.... if the basin has gaps, or if the network of pipes is not well thought out, the best filter in the world will be everything. simply useless!

Finally, we must say to ourselves and dare to say it: one day, a breakdown will occur: a machine that has moving parts sooner or later ends up breaking down, it is inevitable!

It is rarely serious, and it is often predictable... This is why we select our suppliers very rigorously.

Having the experience of having worked with a Dutch company for many years, we were surprised by the sale of this company which was relocated to Great Britain. This was followed by problems with deadlines, tax problems (Brexit), poor after-sales service whereas previously the Dutch manager was very efficient...

This led us to make a difficult but more correct decision towards our customers: that of separating ourselves from all the small companies that could disappear overnight, thus leaving us "on the floor" in front of our customers.

This decision reinforces our idea of allowing monitoring and the supply of original spare parts for many years and quickly. Because a drum filter which starts on average 20,000 times per year breaks down, it is inevitable... This can concern a simple sensor, a pump, a motor... You have to accept it or give up and opt for a good old multi-room.

We therefore prefer to offer equipment made in Europe (after-sales service impossible if the filter is made in China or in 'exotic' countries) by solid, local companies capable of responding to our after-sales service requests within 24 hours maximum. This is why you will not see models on our site that are very common on the Internet...

ANNEX

A question often arises regarding filters in pumping mode.

We saw that what differentiated a pumping model from a gravity model was the location of the level sensor, as well as the arrangement of the piping. The majority of filters have 110 mm inlets which must be reduced to 50 or 63 mm depending on the diameter of the water inlet pipe(s) of the pool pumps.

Concerning the outlets, they are always 110 mm: but depending on the models and brands, these outlets can be located at the top, or at the bottom, sometimes there are both: therefore high and low outlets.

It is imperative to keep a minimum height of water under the drum, a reserve, in order to protect it from deformation when it is full. Without water around the drum, the latter would weigh very heavy and the membrane would deform under the weight of the water.

The recurring question concerns drum models with low output: how to preserve this membrane?

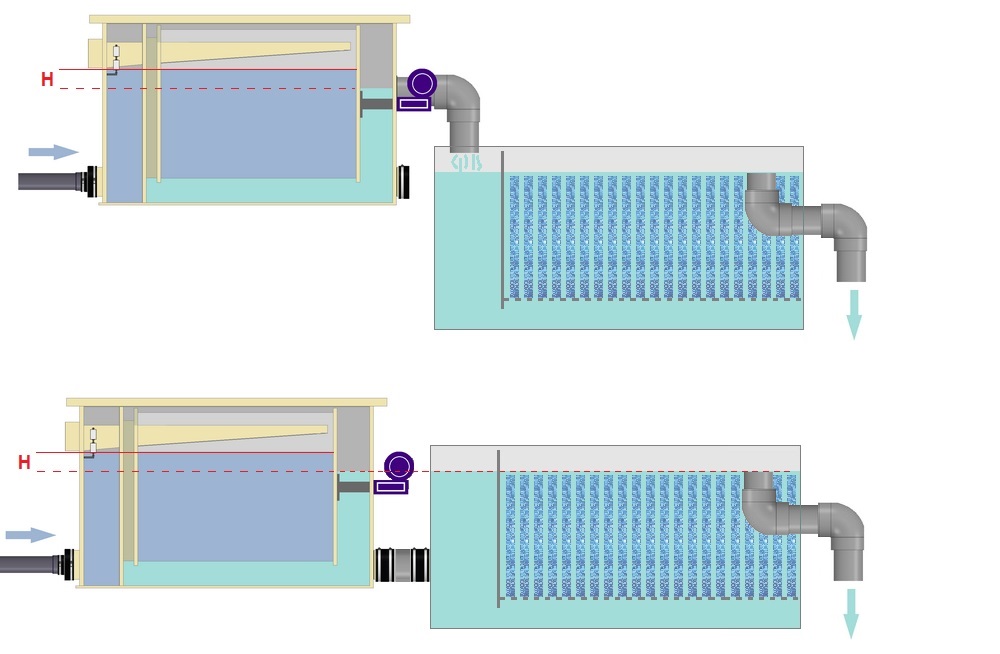

Below you will see two methods of connecting a pumping filter with a biological tank.

The first diagram represents a classic outlet located at the top of the filter: the bottom diagram represents the connection of a biological tank with a drum whose outlet is located at the bottom.

INTELLECTUAL PROPERTY

It is strictly prohibited to reproduce any content or element from the bassin-baignade.eu site without having first obtained the express written authorization of Naïades. All elements such as texts, photos, videos, images, diagrams and other data appearing on the site are protected by intellectual rights belonging to Naïades. Without the prior written consent of Naïades, it is prohibited to use, reproduce, modify, publish, distribute, send or sell any of the elements on this page.