-

Français

Français

-

English

English

No products

Prices are tax included

BIOLOGICAL FILTRATION MEDIA

When the water has undergone a first treatment ridding it of its largest particles, it can then pass through the biological filter. With the supports, the latter shelters the bacteria useful for water purification. For more information on water purification, see the nitrogen cycle in the pond chemistry section.

Before reviewing the different filtration systems, I will detail the main types of media that can be used in a biofilter. The advantage of a bacterial support is to offer a maximum surface area for bacterial colonization, while offering the possibility of good water circulation, but this is not enough...

If the support is not suitable, the bacteria can suffer from “stress”! Under these conditions, they will neither be able to grow nor multiply because their metabolic functioning is slowed down. Some conditions can place bacteria under stress; for example, significant variations in the physicochemical parameters of water, or even the poor quality of a support.

When a cell comes into contact with a surface, it can attach to it temporarily or permanently; the forces of attraction that come into play are chemical and electrostatic.

Let's say that if a surface is positively charged, and the ionic layer around the bacteria is negatively charged, there will be a strong attraction between the two. At the material level, a smooth surface condition does not allow optimal development of the biofilm. The speed of the water current and the light also have an influence...

But if all the conditions are met, we then witness the resumption of normal activity; growth occurs and after a few division cycles, the new bacteria break away from the parental cells to colonize another surface.

Biological media are classified into two categories: media for fixed, therefore immobile beds, and media for mobile baths (moving bed). They are all well ventilated but the second category requires greater air flow to ensure the movement that is necessary.

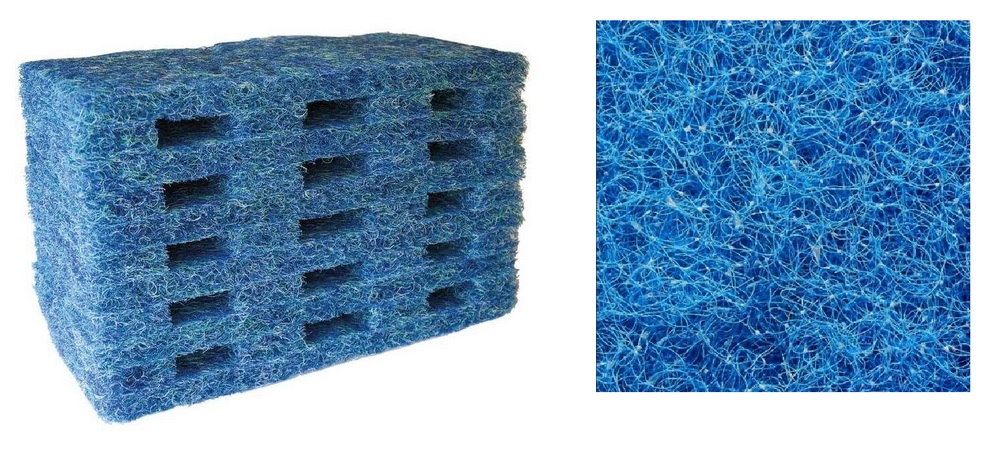

JAPANESE MAT

It is undoubtedly the most used material in fixed bed biological filtration!

These mats offer an airy structure which allows good passage of water while providing a quality surface for bacterial colonies. They are placed in the filter chamber in a vertical position, placed not on the bottom of the chamber but on a grid, and often separated from each other by dividers (made from scraps of carpet).

If the preceding mechanical filtration is of the "ultrafine" type such as a drum, it is possible to do without interlayers and the mats can be installed against each other, if this proves necessary (lack of space).

The direction of the mats is controversial but for my part - in a multi-chamber filter - they are placed perpendicular to the direction of the water flow: this promotes the penetration of the fluid into the mat while reducing dead zones. Given its structure, this carpet does not require any special maintenance. If the biological filter consists of a single large chamber, then it is better to place the mats in the direction of the water flow.

If the mechanical filtration located upstream is not effective, the mats get dirty more quickly and you simply rinse them with pool water alternately. Strong ventilation, which is necessary for bacteria, should also normally prevent dirt deposits in carpets.

The thickness of the mats is 3.5 or 3.8 cm and measures either 1.2 m / 1.0 m or 1.0 m / 2.0 m.

These mats offer a surface area of 275 to 300 m² per m³.

The surface is ultimately average compared to other media, but the material of these mats as well as its texture make it an essential media capable of supporting resistant bacterial colonies.

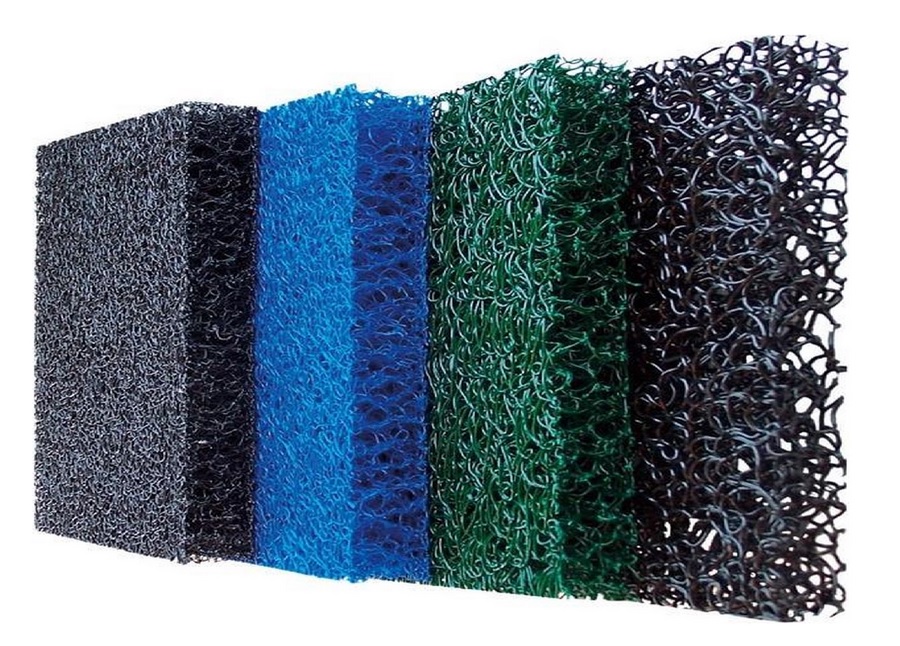

MATALA

The manufacturer offers a range of different polypropylene products including ordinary mats but also tubes or circular mats. Circular mats can be used in vortices (see mechanical filtration). In multi-chamber filters, ordinary mats may work very well; like Japanese rugs, they are easily cut using a grinder and they are available in several densities.

Low density mats are mainly intended to distribute the flow of water in the room: this allows relative settling and avoids clogging of the following mats. We can also create independent mechanical pre-filters using exclusively black matalas.

Average carpets, just like Japanese carpets, harbor nitrifying bacteria ensuring nitrification. As for the carpets with the highest densities, these offer increased performance. After mechanical filtration by drum, it is possible to create a biological filter alternating Japanese carpet and Matala. A good compromise !

Matalas are available in mats measuring 1.00 m by 1.20 m and 4 cm thick and are also used as a fixed bed.

Density of Matala according to color:

Matala black: 140 to 165 m²/m³ (M-150)

Matala black: 180 to 200 m²/m³ (M-190)

Matala green: 270 to 300 m²/m³ (M-280)

Matala blue: 360 to 400 m²/m³ (M-380)

Matala gray: 450 to 500 m²/m³ (M-500)

Matala brown: 580 to 650 m²/m³ (M-650

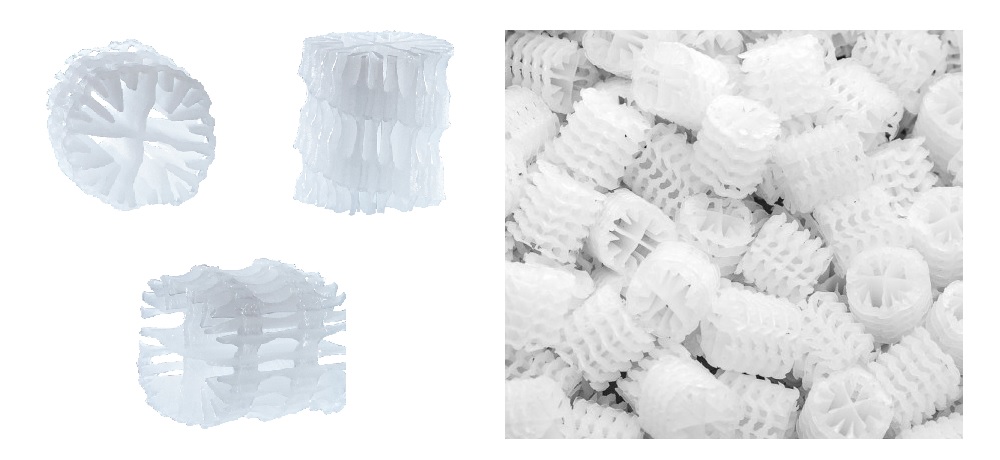

HEL-X

Helix or Hel-X are media to be used in fluidized type filters. The elements are therefore not piled up in a filter compartment, but circulate within it, forced by a flow of air.

The best known support which has a surface area of 595 m²/m³ is Hel-X 17* and whose density is slightly less than 1 to allow flotation. When the biofilm has developed, the density of the material is normally close to 1, and this property therefore allows the material to be perfectly fluidized.

In the case that mainly concerns us, that is to say nitrification, the designers recommend strong ventilation of the chamber to ensure the movement of these media. A slightly smaller version Hel-X 13 is based on exactly the same principle but offers a surface area of 955 m2/m3. *

When the bath is in motion, the particular shape of these media allows, through friction, to permanently remove the dead tissues placed on the external face of the support.

Thus, according to these researchers, the biofilm is constantly regenerated and therefore more effective.

Some are made of PP, others are made of plastic: the latter, made of plastic or recycled material, do not allow optimal biology.

* Hel-X 17 has a total useful surface area of 595 m2/m3 including 496 m2/m3 protected.

* Hel-X 13 has a total useful surface area of 955 m2/m3 including 806 m2/m3 protected.

HEL-X FLAKES

The Biocarrier Helix tablet constitutes an innovation in the field of fluidized bed filters. This white pellet (a black version also exists) has a diameter of 30 mm and a thickness of 1.1 mm. It has a specific surface area for bacteria of more than 5000 m²/m³, which is on average 5 to 6 times greater than that of media usually used in fluidized bed filtration.

High performance Hel-X Flake is made from HDPE just like regular Hel-X. However, the active surface results from a special porous structure of the plastic body. Because this material is smaller, it requires less energy to move it in the water.

BACTERIA HOUSE TYPE CERAMICS - BACTERIA HOME

Bacteria House media is a fixed bed media mainly intended for trickle filters, therefore fixed bed.

The bacteria ensuring optimal conversion of ammonium into nitrites then into nitrates attach and settle very quickly on this material, but also ensure a reduction of nitrates inside these porous cylinders.

Used by certain large farms in Japan, this material, which has been heated to high temperature, is therefore very porous and, according to the manufacturers, develops a colonizable surface area of more than 4000m2/m.

Currently the market offers countless versions, the best known being that of the Momotaro farm.

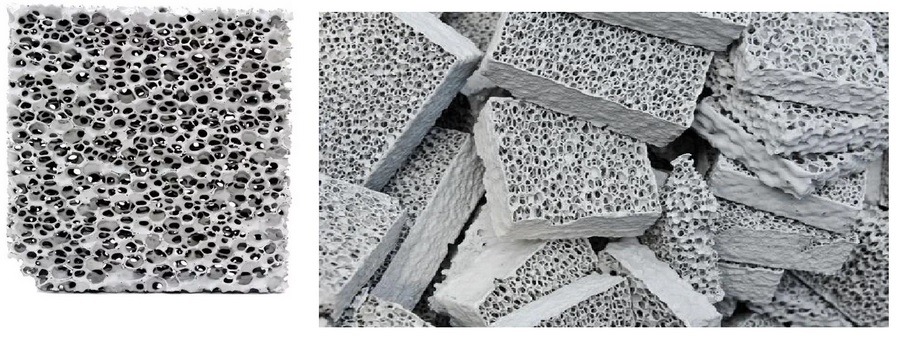

BIOCERAPOND TYPE CERAMIC

The very porous network shape also gives this material a very high bacterial attachment surface.

The bacterial colonization surface of Biocerapond varies from 1450 to 3000 m2/m3 depending on the variable density of the elements. It is used as a multi-chamber or trickle filter where it is most efficient. Its density of 350 kg/m3 makes it a relatively light material whose porosity allows water to pass through the elements.

GLASS FOAM

Made from glass, heated to more than 900°C, this material has a very large colonization surface due to its porous structure, which allows the propagation of aerobic bacteria. These elements are slightly alkaline and can buffer the pH of the pond water.

Extremely light, it is ideal for trickling filters due to its very attractive price.

POZZOLANE

The term “pozzolan” comes from Pozzuoli, an Italian town located near Naples (Vesuvius). Pozzolan is a volcanic rock with a honeycomb structure, whose composition varies depending on the extraction site: it is not found exclusively near Vesuvius... numerous quarries exist, for example in Auvergne.

This rock is very microporous, so it can harbor a large colony of bacteria useful for our filter. The porosity of a material is estimated by measuring the volume of water necessary to saturate a given volume of this material.

This advantage does not provide an extraordinary surface area for bacteria; it is not just the surface area that must be taken into account, but it makes it possible to significantly shorten the start-up time of the nitrogen cycle.

The biofilm clings faster and more easily than on synthetic supports, even faster than on ordinary gravel. A second particularity of pozzolana is to extend the residence time of nitrogenous waste in trickling filters: this does not mean that the water stays longer in the filter, it means that the structure of the pozzolana allows it to be retained for longer. the particles.

With better oxygenation, this explains why semi-humid filters have better efficiencies than filters with submerged supports.

In this configuration, without super efficient mechanical filtration, pozzolan is the champion for trapping MES: for proof, simply rinse a compartment filled with this rock and compare with a second filled with synthetic substrate...

This quality makes it a big flaw: few have very effective mechanical filtration and in this case, it is therefore necessary to endeavor to regularly rinse these filter masses by placing them not in bulk in the filter, but in bags or baskets to facilitate handling.

This material should therefore only be used in filters which benefit from very fine mechanical pre-filtration, and for swimming only!

The clogging of a porous material is not only due to SS (physical clogging), because bacterial activity also produces sludge and by-products which can clog the pozzolana (biological clogging).

If denitrification is possible in an unclogged porous material, a clogged filter that is not well maintained can very easily cause fermentation, a phenomenon that must absolutely be avoided.

This material is therefore no longer widely used except in swimming after a very fine mesh drum filter and by combining several calibers.

PLASTIC MEDIA

Plastic media are often offered with the purchase of a filtration system and are well suited for starting a new installation, when the budget requires some "adjustments"!

They exist in many forms and among these, bioballs are the best known.

In general, these are poor quality media which have a relatively modest surface area (150 to 200 m²/m³): comparing with other products, you must therefore plan for much more. For this type of material, it is better to refer to reputable brands because the composition of plastics varies greatly and the risk of toxicity is not zero: certain chemical substances can migrate and diffuse in water (cadmium plastic etc.)

Concerning the biofilm: it clings well to the "plastic" if it is rough: an irregular texture often makes the difference with a product with a smooth texture which is better to abandon. The advantage of these materials is to avoid clogging of surfaces. First price material, for first price filter.

ZEOLITHES, ACTIVATED CARBON, OYSTER SHELLS AND OTHERS

These are NOT bacterial carriers but water treatment products!

To be used occasionally for temporary problems.

INTELLECTUAL PROPERTY

It is strictly prohibited to reproduce any content or element from the bassin-baignade.eu site without having first obtained the express written authorization of Naïades. All elements such as texts, photos, videos, images, diagrams and other data appearing on the site are protected by intellectual rights belonging to Naïades. Without the prior written consent of Naïades, it is prohibited to use, reproduce, modify, publish, distribute, send or sell any of the elements on this page.

![]() 2024

2024