-

Français

Français

-

English

English

No products

Prices are tax included

Mechanical filtration

Filtration certainly experiences the greatest diversity in its developments, and this is undoubtedly the reason why the subject is sometimes difficult to define. Many products are available on the market, and as in other areas, some are very efficient and others less so.

Faced with the growing offer and relatively aggressive marketing, it is better to remain unmoved and ask yourself the right questions before making a final choice.

Fed by a constantly polluted body of water, the filter must satisfactorily meet two main criteria: it must be capable of neutralizing, within a well-determined time, toxic nitrogen waste, and of increasing the clarity of the water. to a degree of quality which, in this case remains entirely relative.

Although in many cases it is possible to obtain honorable results with a single filtration line, it is sometimes essential to use several separate circuits to make the pool perfectly clear and healthy.

Concerning the biological aspect: whatever the nature of the support, its surface must be able to shelter sufficient bacterial colonies essential for purification. The volume of the biological filter is therefore directly linked to the quantity of food distributed daily, as well as to the number and nature of the fish.

Concerning the clarity of the water: even if this is important, it is not only a question of worrying about the aesthetic aspect of the pool. The biological filter cannot be fed with water loaded with suspended solids (MES); without prior mechanical filtration, the supports become unnecessarily dirty and make nitrification more uncertain. The second reason is more subjective but if you create a body of water, it is to see your fish....

Reading the preceding lines, we can already conclude that:

- the small filters that are very frequently encountered in garden centers, DIY stores or at certain poorly informed retailers, are much too small to provide any satisfaction for fish maintenance.

- we must clearly distinguish two types of filtration: biological and mechanical. Sometimes, some filters perform both phases simultaneously.

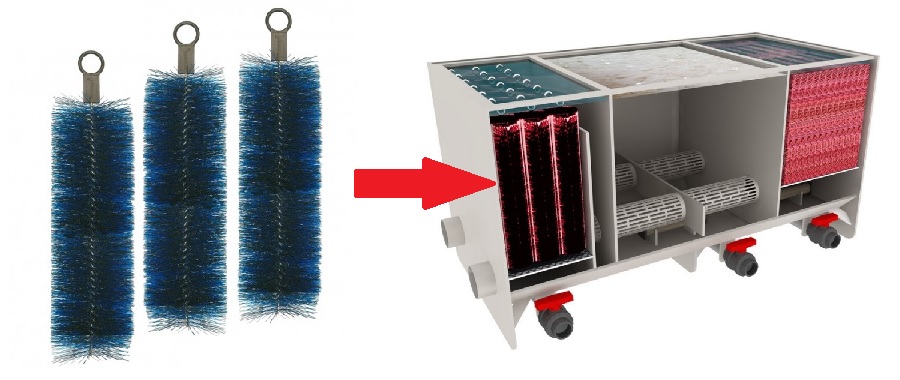

Brushes

Brushes constitute the most basic system of mechanical filtration! They are made of polypropylene wires held by a twist of stainless steel wires.

Placed in the first chamber of a filter, these brushes are suspended or placed on a grid, and tightly tightened, they constitute a barrier in which the MES will cling to it.

Note that the fibers of these brushes will "hook" particles in suspension by mechanical effect, but they will also attract particles to them by electrostatic effect.

Several diameters as well as different lengths are available; maximum filling of the chamber is essential, the diameters 10 and 15 cm are clearly preferable to the larger diameter (20 cm) which allows too much dirt to pass through.

Regarding the length, simply choose it according to the height of your filter. Normally, as the water enters through the bottom of the filter, a free area of approximately 10 to 15 cm must be left under the brushes: the speed of the water is relatively slow and constant. After a while, we can see the effectiveness of the system: the brushes are filled with dirt and when the deposits are very heavy, they should be cleaned by successive rinses.

Inevitably, nitrifying bacteria will settle in the brushes and although this is primarily mechanical filtration, a biological action also takes place.

Without providing extraordinary clarity, the brushes constitute an effective means of reducing the MES in a pool at a democratic price. In summer, these brushes quickly become quite busy and they need to be cleaned very regularly. In order to reduce this maintenance, it is sometimes preferable to precede these brushes with another device: the vortex or a grid pre-filter.

The Vortex

The vortex is a circular decanter which is installed between the basin and the filtration: the principle consists of passing the water to be treated in a tank to allow the MES to flow to the bottom by gravity.

Like all decanters, the speed of the water must be adapted and, given the significant height of a vortex, the latter must be wide enough to allow the lightest solids to descend to the bottom of the tank. In other words, a minimum transit time must be obtained in order to achieve good results. The large volume required means that little by little, more modern means are replacing this system.

On a practical level, the vortex should only operate in gravity mode (basin level = vortex level): otherwise, a pump placed upstream only chops up the particles, making them more difficult to settle.

As we have seen, the speed of the water is preponderant and the pump flow must therefore be in line with the size of the vortex, or more precisely, with the actual volume of water passing through the tank. The detail is important, since it is the height which separates the inlet/outlet conduits which determines this volume and not the total volume of the tank.

Under these conditions, it is difficult to give precise indications as to the flow rates to be respected; however, if the vortex responds to what has been described, the following extrapolations can be accepted:

Vortex with a minimum diameter of 80 cm: maximum flow rate of 6 m³/hour.

Vortex with a minimum diameter of 100 cm: maximum flow rate of 11 m³/hour.

Vortex with a minimum diameter of 120 cm: maximum flow rate of 18 m³/hour.

These average indications allow the decantation of the densest particles because a vortex, however efficient it may be, does not allow the decantation of all the MES. This is a first treatment which must be followed by more effective mechanical filtration. In this case, the vortex is followed by a brush compartment; this duo constitutes an average mechanical filtration which often gives satisfaction.

In recent years, this system has begun to be neglected: too bulky, the vortex does not remove waste from the system and if we do not intervene very regularly, the waste very quickly degrades the quality of the water. It is therefore necessary to intervene often.... Below are two different examples of vortex.

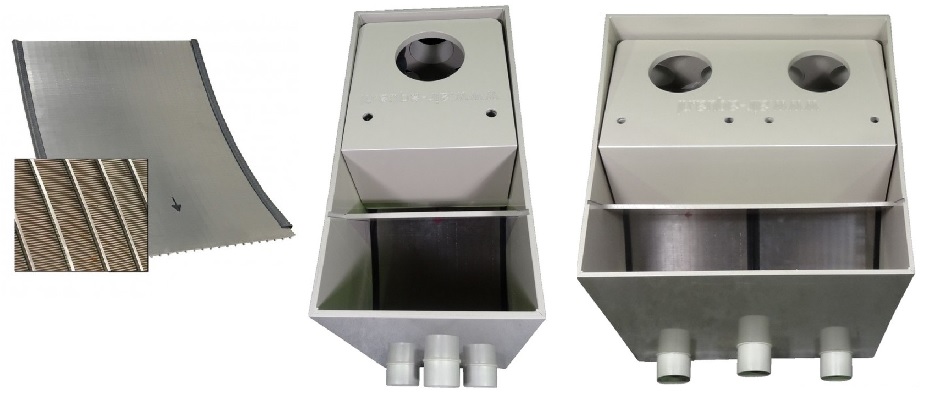

Grid pre-filters

The principle of these pre-filters consists of sliding water over a grid pierced with calibrated orifices of 200, 250 or 300 microns, thus ridding it of particles which are discharged into the drain.

The water from the pool enters the pre-filter: in gravity, a level regulation system activated by a float makes it possible to maintain a constant level in a compartment of the tank. While in pumping mode, the water flows onto the grid then into the biological filtration by gravity.

If the brushes are superfluous after this type of pre-filter, in gravity mode, this is not the case in pumping mode where it is essential to maintain them! There are now a number of models of grid pre-filters for both pumping and gravity mode. The standard 300 micron grid is the most common: the 200 micron size is also available but requires many more cleaning interventions.

In itself, maintaining a grid pre-filter does not require a lot of time but they are frequent (1 to 2 times per week for a 300 micron, sometimes more for a 200 micron) and this frequency can quickly become a chore.

Periodically, the grille must also be dismantled for more in-depth maintenance because ultimately a biofilm settles in the gaps and the grille is clogged.

Drum filters

This type of filter is very different from the above for two reasons: the first is the fineness of filtration obtained which is much greater since particles of 50 to 120 microns are retained depending on the model (instead of 200 microns, at best, with a grid pre-filter).

The second is that this type of filter is self-cleaning. Used mainly in gravity mode, it precedes biological filtration and allows you to obtain a clear pool without having to undertake a lot of maintenance work.

The operation is very simple: it consists of passing dirty water through a filter membrane. When this membrane is dirty and therefore clogged, a device initiates cleaning by rotating the drum and spraying clean water. The waste is evacuated to a sewer: there is therefore no regular cleaning operation. However, it remains to monitor the condition of the main components of the filter from time to time.

A UV immersion lamp is often integrated into the drum, to reduce energy costs, and in certain cases, to limit the development of biofilm on the membrane. This being said, it is not at all essential to irradiate the filter screen with a UVC lamp: if the rinsing pump generates sufficient pressure, it can keep the screen in a good state of cleanliness

On the other hand, it is essential to descale the sieve regularly: limescale being the real source of progressive clogging of a sieve, regular treatment with acid is recommended, the frequency of maintenance depends on the kH of the water but remains easy and not a chore.

The drum filter really presents a big advantage compared to filtration with brushes or grid pre-filter, it is offered alone, or accompanied by biological filtration, this is what we call a Combi.

In the first case, the drum is integrated into an existing filtration, or to be carried out, in the second, the Combi is ready for use.

These sophisticated filters have been around for around twenty years and have been made popular primarily by Dutch and German companies who dominate the market. Currently, there are medium ranges in polypropylene or premium ranges in stainless steel which can even be connected.

The sieve filter (endless ribbon type)

The principle of mechanical filtration is similar to the drum filter: instead of a rotating drum, we find a filter membrane cleverly arranged in the manner of an inclined plane. This Nylon membrane is sprayed during cleaning like that of the drum filter.

This self-cleaning filter has the same performance as a drum filter. Below the mechanical filtration which retains the particles, there is a biological chamber in which a fluidized bath of media ensures biological purification. The performance/land footprint ratio is the best and this filter can also operate in pumping or gravity mode.

INTELLECTUAL PROPERTY

It is strictly prohibited to reproduce any content or element from the bassin-baignade.eu site without having first obtained the express written authorization of Naïades. All elements such as texts, photos, videos, images, diagrams and other data appearing on the site are protected by intellectual rights belonging to Naïades. Without the prior written consent of Naïades, it is prohibited to use, reproduce, modify, publish, distribute, send or sell any of the elements on this page.

![]() 2024

2024